Laminar Flow Aeration Technology

Aeration is required for mixing and to maintain dissolved oxygen (DO) levels at every wastewater treatment system, whether a lagoon or treatment plant. Low DO levels cause anaerobic conditions and odor problems in lagoons. Laminar flow aeration technology will help resolve odor and sludge problems by mixing the lagoon with columns of fine bubbles.

FACT: AN AEROBIC ENVIRONMENT IS NEEDED FOR THE MOST EFFICIENT AND ODOR FREE WASTEWATER TREATMENT!

Laminar flow aeration is the solution to maintaining proper aerobic conditions

ProLake™ Laminar Flow Technology for Lagoon Aeration and Mixing

ProLake™ has invented elegant, yet simple, solutions to the problem of aerating waste water lagoons. ProLake™ has designed aeration systems utilizing solar powered or low horsepower, electrical, sub-surface diffused aeration. Expandable rubber membrane diffusers produce a laminar flow of bubbles. This type of diffuser has thousands of tiny openings that create small fine bubbles at low flow.

A laminar flow of small bubbles is advantageous in that they have a greater surface area for the absorption of oxygen into the water. Additionally, the smaller bubbles in a laminar flow move slower than larger bubbles which provides additional contact time. Also, because the smaller bubbles have a greater surface area, the laminar flow of bubbles pushes water vertically to create a columnar flow of water.

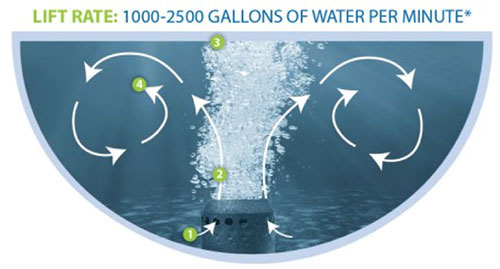

The Duraplate™ Diffuser directs the laminar flow of bubbles and assists in creating a columnar flow of water that is drawn from hole at the bottom of the tube. This creates circulation of water from the bottom of the body of water.

Laminar flow aeration systems create a roll pattern in a lagoon for complete mixing.

- The diffuser pulls in the Water

- The water is Oxygenated

- Water is transported up to the surface

- A laminar current is created