Why lose all of the progress you made treating and maintaining your pond all summer? As the heat of the summer simmers down and the weather starts to cool, RV parks, campgrounds and other lagoon and pond owners are preparing to hunker down for the winter. What these owners may not realize is that their

New regulations are on the horizon for most of the United States and will affect many owners of conventional septic systems. The owners of these systems, especially if the septic system is old and/or poorly maintained, may face the prospect of converting to an aerobic treatment process. We have heard from a number of owners

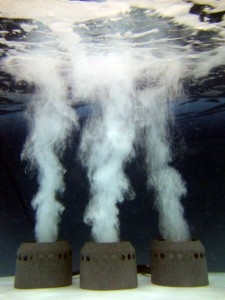

Introducing air to a wastewater treatment system or, lagoon or pond is vital to maintaining proper dissolved oxygen (DO) levels for sewage treatment. The process of introducing air is called “aeration”. Aeration brings the wastewater being treated into contact with air with some of the air being absorbed by the wastewater. The aeration process typically

Everything done so far has been in the pursuit of two basic goals: Create an aerobic environment for optimal waste digestion and water quality Provide beneficial bio-enzymes and microbes for wastewater treatment and solids digestion Now that the equipment has been installed, it must to utilized as part of a program in order to achieve

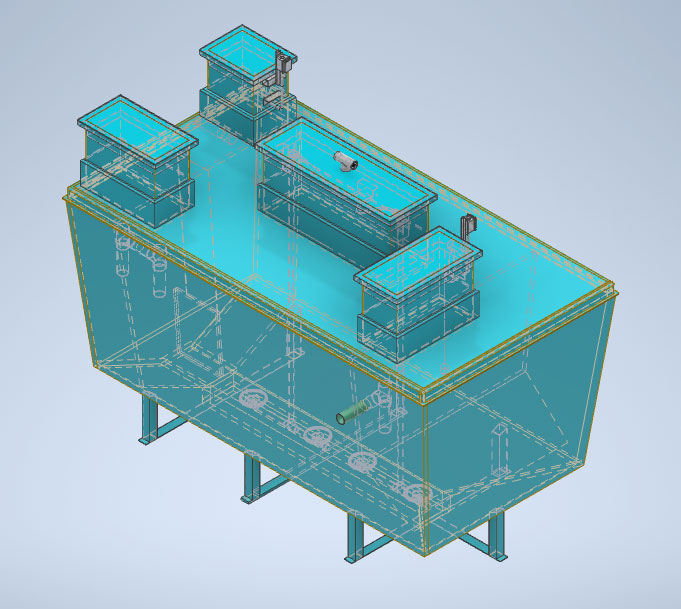

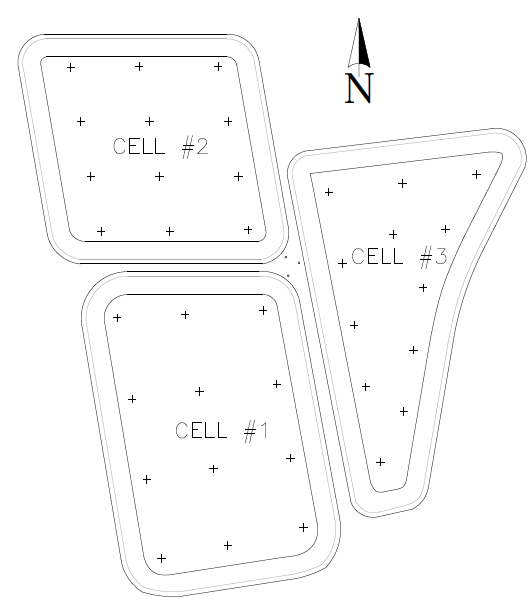

Now that the system layout has been designed, the equipment procured, and the lagoons and site are prepared, it’s time to deliver the equipment and install the aeration system. Delivery If we are assisting you in the installation of your system, we will deliver the equipment ourselves. If you need a boat, we can supply

What Goes into The Aeration System The aeration system consists of the air delivery system or “air compressor”, weighted tubing and diffusers. We also use small buoys which attach to the diffusers with a cord so the diffusers can be located and retrieved easier after they are installed. General Wastewater Lagoon Aeration System Design We

Introduction This is a four-part series of blog posts which describe a typical wastewater lagoon rehabilitation. Our hope is that we can provide a little more understanding of how our process works and what to expect. This series will walk you through each step of the process including what needs to happen before, during after

Don’t ignore odors coming from your septic tank. Solve them or the problem will only get worse! If you have a septic tank, you should be able to use it problem-free, for years. However, it’s not unusual to experience septic odor problems with a septic system. Regular septic tank maintenance is vital to long-term, trouble