What Goes into The Aeration System

The aeration system consists of the air delivery system or “air compressor”, weighted tubing and diffusers. We also use small buoys which attach to the diffusers with a cord so the diffusers can be located and retrieved easier after they are installed.

General Wastewater Lagoon Aeration System Design

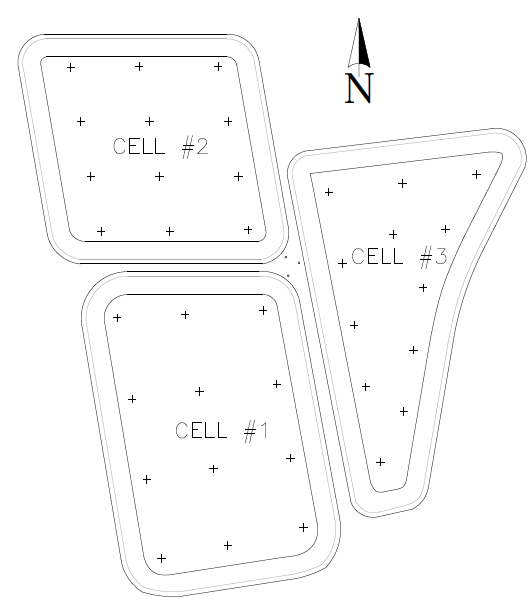

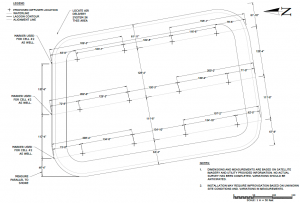

We look at the surface area, depth and shape of the wastewater lagoons to determine the best placement for the diffusers for uniform mixing. We also look at the best place to install the aeration system air compressors and approximate how much tubing will be required to deliver air from the compressors to the diffusers.

Designing the Diffuser Layout

We will usually lay a grid out on each lagoon and place the diffusers along strait lines at equal spacing. Some lagoons are odd shaped and require a bit of flexibility on diffuser placement. The goal of this stage is to make the installation as easy as possible by planning everything out ahead of time. The design will include the location of alignment stakes that will be used to drop the diffusers where they need to go.

Locating the Aeration System Air Compressors

The aeration system air compressors should be located in a location that minimizes the length of tubing required to get air to all of the diffusers. Access to a power source is another consideration. If multiple compressor units are needed for aeration system, we will want to locate them in the same area if possible.

The air delivery compressors should be installed in a central location. Notice the 3 tiny boxes in the space between all of the lagoons. In this case, this is the optimal location to limit the amount of air tubing required for the system and make maintenance of all of the units easier.

Equipment Procurement

Typical lead time for procuring the aeration system air compressors, diffusers and associated equipment is currently about 3-4 weeks. We will collect all of the equipment at our warehouse to deliver it all together.

Site Preparation

Once the design is all set and the equipment is placed on order, a few things need to be in place at the site prior to delivery. During this time it is a good idea to prepare the lagoons or ponds and the surrounding area for installation. A smooth installation is highly dependent on how well the site is prepared!

- Adequate power needs to be provided at the location where the aeration system(s) are to be installed. If the unit is a 220 volt system, you will need a dual breaker for the unit and a small 220 plug (not a dryer plug).

- Each aeration system air compressor unit will require a pad or appropriate surface to set it on. This can be a concrete pad, crushed gravel base or we can provide a pre-manufactured base with the unit that is built for this purpose. Please note that a dirt surface will likely cause the compressor unit to ingest dust. Grass is also not a good surface to mount the compressor on because it can grow tall enough to possibly interfere with the operation of the unit

- If there is a large amount of duckweed or vegetation on the surface of the lagoon or pond, it should be cleared as much as possible

- Any debris or trash on or around the lagoon or pond needs to be cleared

- If weeds, tall grass or shrubs growing around the shore of the lagoon or pond, it should be cleared as well

- A boat that can carry four men with a trolling motor will be needed for placement of the diffusers. We can provide a boat if necessary when we deliver the equipment

- A road or cleared access large enough the get the equipment close to or at the installation site

Now that the lagoon aeration system had been designed, the site prepared, and the equipment is on it’s way, the next step is delivering your equipment and installing it.

See the next installment “Part 3” for our blog post about delivery and installation day.